IATF 16949

Buzas Laser Service has the most important certificates in the automotive field. One of them is IATF 16949. Which is an international standard that establishes requirements for quality management in the automotive industry. It differs from other standards by having specific requirements for the sector, in addition to including the requirements of ISO 9001.

IATF 16949 is important because:

Ensures that companies in the automotive sector comply with the requirements of the standard.

Contributes to continuous improvement, waste reduction and defect prevention. It allows companies to stand out and negotiate with international customers.

Contributes to business security and stability.

Strict Requirements: The standard not only incorporates the requirements of ISO 9001, but also adds automotive sector-specific requirements such as risk management, process control and quality assurance throughout the supply chain.

Commitment to Quality: To obtain certification, companies must demonstrate an ongoing commitment to improving processes and reducing variations and defects, requiring significant investments in training and technology.

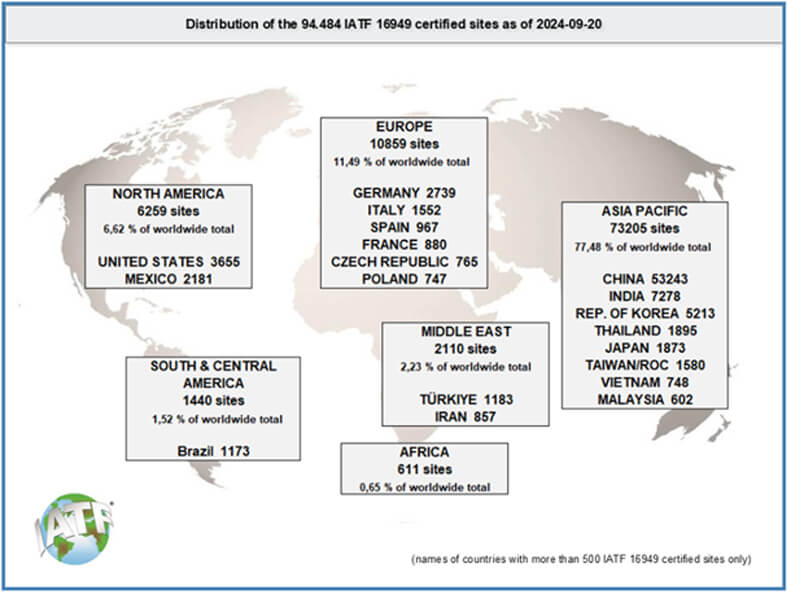

Select Group: Just 1173 empresas in Brazil, IATF 2025, they are certified by IATF 16949. This quantity reinforces the idea that certification is an important achievement and a sign of distinction in the market.

With excellence in work, pursuit of quality, customer satisfaction, improvement of the production system, expansion of the industrial park and investment in new technologies, Buzas has been awarded the ISO 9001 certification since 2003 and the registration certificate for supply to Petrobrás CRC.

With all this quality and excellence, Buzas serves the domestic and foreign market in various market segments, always with the best quality standard.

The investment in new technologies, training and qualification are constant. Buzas is equipped with a three-dimensional measurement control 3D FARO measuring arm and has a highly qualified technical team for quality control.

Today, all production processes undergo quality control from conception to shipment.

The efficiency, innovation and sustainability of Buzas boilermaking solutions have made it a reference in product development. Based on the Lean Manufacture philosophy, with a project methodology that integrates tools such as APQP, FMEA and PPAP.

Process audit standard aimed at the automotive industry;

Developed by VDA (Association of the German Automotive Industry);

Evaluates the ability of production processes to meet quality requirements;

Focuses on identifying and mitigating risks throughout the production chain;

Used as a tool for qualifying suppliers;

Covers planning, series production, failure analysis and continuous improvement;

Fundamental to meeting the requirements of global automotive manufacturers;

| Cookie | Duração | Descrição |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |